Copyright Independent Balkan News Agency, 2021

https://www.pioneerindustrial.com/wp-content/uploads/2021/11/Biogas-Plant.jpeg

1048

2000

Karrie Williams

https://www.pioneerindustrial.com/wp-content/uploads/2020/12/Pioneer-Logo-Color-min.png

Karrie Williams2021-11-17 21:25:392021-11-17 21:25:44Waste Burner Systems

Copyright Independent Balkan News Agency, 2021

https://www.pioneerindustrial.com/wp-content/uploads/2021/11/Biogas-Plant.jpeg

1048

2000

Karrie Williams

https://www.pioneerindustrial.com/wp-content/uploads/2020/12/Pioneer-Logo-Color-min.png

Karrie Williams2021-11-17 21:25:392021-11-17 21:25:44Waste Burner Systems

Boilers systems are abundant in the domain of industrial equipment. They can be found in a variety of applications: healthcare, power generation, oil/gas industries, manufacturing, chemical plants, and more. So why do so many different industries use this type of equipment?

A report conducted by Energy and Environmental Analysis, Inc. found that there are close to 4.7 million commercial buildings within the U.S. Of these buildings, around 12% of them are served by boilers. Though this, we can indicate that there are over 500,000 pumps being utilized in commercial boiler operations. That’s no small number.

Boilers and steam production may be more common than you think in everyday operations. For example, a hospital may have boilers that produce steam for their own power generation or heating systems. Some small communities (or subsets of communities), like a university campus, may have their own steam generation plant. This steam can be distributed throughout piping on campus and can then be condensed to heat the buildings. Essentially, this allows a campus to provide its own heating power independent of the local energy grid. Moreover, excess steam can be sold to neighboring buildings or communities as well.

Steam Production – Boiler System & Feed

Steam production is fairly straightforward, as steam is simply superheated water. There are various methods of doing this, but at its core the water is heated in a boiler.

A boiler can burn various fuels to create the heat needed to vaporize water. For example, No. 6 fuel oil is a grade of refined oil that is common in these types of heating applications. In another vein, you could have a boiler that is fed by burning wood chips, Or, in the case of a more environmentally conscious steam production, you might see other cleaner-burning natural gases being utilized to generate the heat. The choice of fuel is ultimately up to the producers economic and environmental specification. These choices are either derived from governmental regulations or corporate decisions, and often both.

We know have the means to start our steam production. Let’s now take a look at how these boiler systems function.

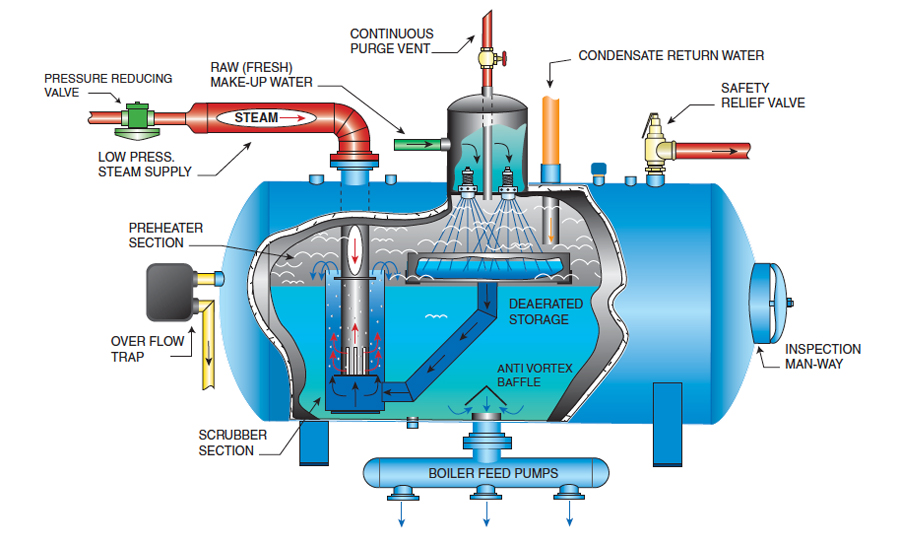

A boiler itself is a pressurized tank, and it uses pumps to move water through a system. Among those pumps, there are three basic types:

- Boiler Feed Pump – pumps water directly into the boiler through tubes

- Condensate Pump – collects used, residual water and recycles it through the system

- Deaerator Pump – Removes impurities in the system

These systems operate with high pressure because of the high water temperatures involved. So, in pumping applications, other pumps like a horizontal split case, barrel, ring section, enclosed stacked can, and vertical turbine can be necessary for proper operation.

The feed is an essential component of any boiler system. The water that goes into the boiler vessel, and the mechanism that gets it there, are both critical. So, a boiler feed pump must be properly selected for the conditions. It then must be installed properly and regularly maintained (per manufacturer recommendations) to ensure it runs as intended.

The fluid sealing on the pump must also be diligently monitored and serviced when necessary. A faulty seal in an operation like this has apparent implications. Replacing the mechanical seals in these systems can take hours or days. To remove a standard mechanical seal, the motor, bearings, and coupling must be removed first. After a new mechanical seal is installed, they can be replaced. A split mechanical seal, however, can eliminate hours from the maintenance process due to its efficient installation process. With a split seal, the motor, coupling, and bearings all stay in place. Only the split seal needs to be removed and replaced for maintenance.

As you can see in the previous diagram, there are many moving parts involved in a boiler system. Just as the boiler feed pump is important, so are other various components. For example, a high-quality pressure relief valve ensures that your boiler runs consistently and as intended. To learn more about pressure relief valves and their role in an industrial application, visit our blog post that explores their technology. Likewise, having a reliable safety relief valve offers security in both well-being and financial matters.

Let’s look a little closer at some of the other parts and practices that make boiler systems more efficient.

Properly Maintaining a Boiler System

Since steam is such a critical aspect of many operations, it can be costly if a boiler system goes down. For example, steam may be used in process heat exchangers to moderate the temperature of process fluids in certain chemical processes. Steam may also be used in power generation that drives other important equipment or components. So, a boiler system going down may mean other valuable production lines go down with it.

To avoid these costly malfunctions and potential damage to downstream equipment, the specialists over at B.I.M.S. have a few tips on maximizing efficiency.

- Clean your system regularly. Boilers accumulate debris over time, and debris can reduce heat transfer in boiler tubes. If too much builds up, you may be at risk of a system breakdown.

- Properly insulate your components. Heat lost means more cost. Between fittings, valves, and condensate pipes, proper insulation goes a long way.

- Don’t neglect the quality of water. The water in a boiler can become contaminated for a variety of reasons. Make sure to check for organic matter, dissolved materials, and if your pumps are properly removing condensate and impurities.

- Clean boiler buildup. Different substances like magnesium, chlorides, sodium, and more create scale buildup. Keep it clean to keep your heat transfer healthy.

- Keep your inspection logs straight. Having your records in order will help you know when a routine inspection is needed. Neglecting this simple task may lead you to fall victim to unexpected problems.

Boilers, despite their relative simplicity, are widely used in various industries and help many other processes get done. A reliance on steam production boils down to an equal reliance on the feed systems behind it. It cannot be overstated how important proper maintenance of boiler system, feed pump, and fluid sealing is. Picking the right products and working with the right specialists ensures that your steam production operates as intended.

Copyright Independent Balkan News Agency, 2021

https://www.pioneerindustrial.com/wp-content/uploads/2021/11/Biogas-Plant.jpeg

1048

2000

Karrie Williams

https://www.pioneerindustrial.com/wp-content/uploads/2020/12/Pioneer-Logo-Color-min.png

Karrie Williams2021-11-17 21:25:392021-11-17 21:25:44Waste Burner Systems

Copyright Independent Balkan News Agency, 2021

https://www.pioneerindustrial.com/wp-content/uploads/2021/11/Biogas-Plant.jpeg

1048

2000

Karrie Williams

https://www.pioneerindustrial.com/wp-content/uploads/2020/12/Pioneer-Logo-Color-min.png

Karrie Williams2021-11-17 21:25:392021-11-17 21:25:44Waste Burner Systems

Harnessing Natural Fluid Flows – An Exploration of Alternative Energy Sources Industries

Environmental Safety, Renewable Energy