Pioneer Industrial recommends AMETEK/O’Brien electrical heat trace technologies as a safe, economical way to protect pipes from freezing

Electrical Heat Trace Technology Protects Exposed Pipes

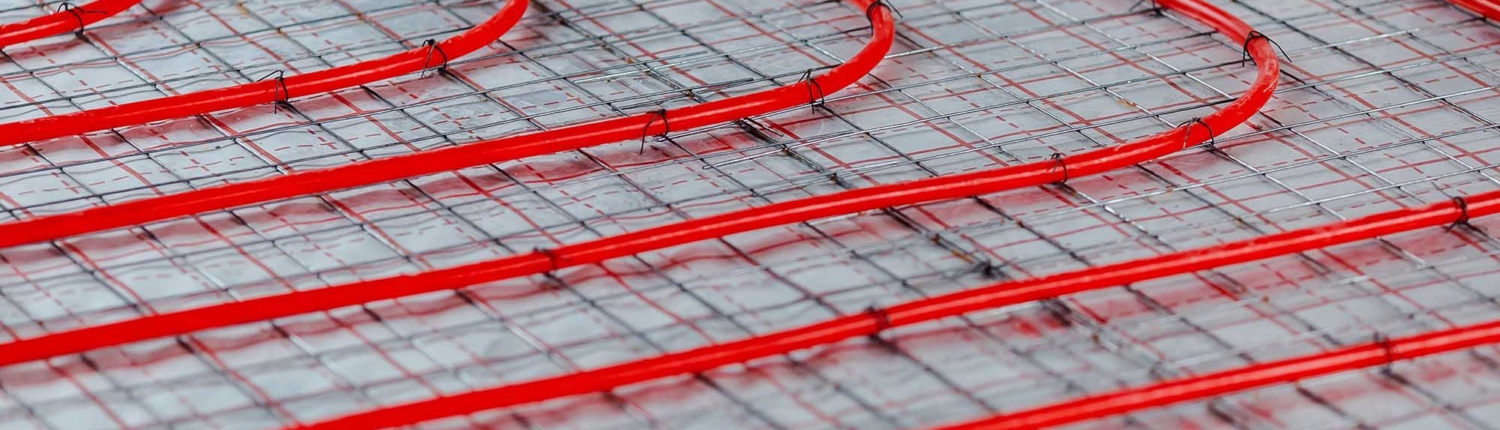

During the year, media temperatures need to be maintained as liquids move throughout the plant, and even industrial buildings in mild climates need to plan for swings in temperature extremes. Winter weather can play havoc with exposed pipes. While many plants use insulation and jacketing to control this temperature, Pioneer Industrial recommends electrical heat trace technologies as a safe, economical alternative.

This blog will explore electrical heat trace technology applications and how Pioneer is the industrial equipment supplier that adds value to the high-quality products we offer.

Understanding how Heat Trace Technology Will be Applied Is Vital to Choosing the Most Suitable Products

Pipe freeze protection – Heat trace technology is frequently used to prevent fluid from freezing and damaging pipes. Cold liquids also have lower viscosity, which slows down or completely stops processes. Industrial plants do not need to be in the polar regions to experience freezing temperatures, and prolonged cold weather can destroy

Process temperature maintenance – Certain fluids such as fuel oils, acids, and fertilizer need to travel at a higher viscosity, and self-regulating technology cannot maintain precise temperatures.

High-temperature heat tracing – Some heat tracing technology applications require the fluids to maintain extreme temperatures throughout their journey through the system. These high temperatures can be maintained through specific heat tracing equipment.

Long-line heating – Circuit lengths of 1,000 feet or more, up to several miles, require heat tracing applications for freeze protection, temperature maintenance, or viscosity control for certain fluids. This sheathing needs to be durable and able to perform in remote locations and harsh environments.

AMETEK/O’Brien Products Offer Industry-Leading Heat Trace Freeze Protection

AMETEK/O’Brien temperature-controlled tubing bundles are the modern way to protect industrial pipes from exposure to freezing temperatures. These products provide winterizing and temperature control for process instruments, manifolds, and fittings both in the plant and exposed in the field.

The Pioneer Industrial Difference

Pioneer Industrial is more than a distributor of specialized heat trace products. We provide solutions to unique and specific industrial issues to better serve our customers. We take the data you provide, including operating temperatures, ambient temperatures, process media, piping type and length, insulation, and specific industrial requirements to ensure the products we provide fit what you need and your intended use. The goal is to provide lasting solutions through high-quality control valves and preventive maintenance.

Reach out to your Pioneer Industrial representative today to find out more about our AMETEK/O’Brien product line and how they can protect your pipes from freezing during the cold winter months.