Copyright Independent Balkan News Agency, 2021

https://www.pioneerindustrial.com/wp-content/uploads/2021/11/Biogas-Plant.jpeg

1048

2000

Karrie Williams

https://www.pioneerindustrial.com/wp-content/uploads/2020/12/Pioneer-Logo-Color-min.png

Karrie Williams2021-11-17 21:25:392021-11-17 21:25:44Waste Burner Systems

Copyright Independent Balkan News Agency, 2021

https://www.pioneerindustrial.com/wp-content/uploads/2021/11/Biogas-Plant.jpeg

1048

2000

Karrie Williams

https://www.pioneerindustrial.com/wp-content/uploads/2020/12/Pioneer-Logo-Color-min.png

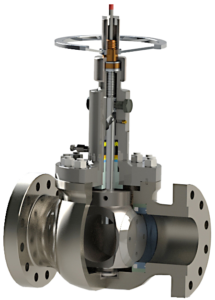

Karrie Williams2021-11-17 21:25:392021-11-17 21:25:44Waste Burner SystemsThis post is product centered on a rising stem globe valve that we want to shed more light on. The valve features technology and specific features that make it stand out against even the toughest competition. Today we are talking about the Union Tech Z4.

The Z-series of valves by UnionTech are designed for high performance and harsh applications: applications where leakage is simply unacceptable. The Z4 is specifically designed as a replacement for traditional ball, gate and plug valves in high performance applications, positive shutoff requirements, and frequent cycling. This can further be specified with soft or metal seating depending on your process conditions.

Sounds like a solid piece of equipment that could work in your process, but what makes it the device you want for your process? That’s what this post is all about: to discuss the benefits and features that are exclusive to the Union Tech Z4, or at least hard to find in competitors’ products. We believe this is a complete package product, and the reasons are the following.

Lead Time Improvements

The Z4 has proven to be faster to your production than many competitors, including the Orbit valve of same specification. We know that lead times can be crucial to scheduling and production at industrial sites. Shorter lead times mean more flexibility when it comes to a working window to complete a project or implementation. It also means less downtime in situations where your process is in a pinch and waiting on replacements. Overall, it means less headaches and more reliability.

The Union Tech Z4 in common sizes are readily stocked and results in extremely low lead times. For more customer engineered-to-spec cases the lead times look at about 26-28 weeks versus the 40+ you would see for some competitors.

Lower Prices

Not only are we happy to get you the product faster, but we can also charge less for the same use case product. The Union Tech Z4 is approximately 30% less in cost than Orbit. Prices vary based on specifications, but the Z4 proves time and time again its economic value over other competitors.

Reduced Costs and Effort in Maintenance

The seating technology in the Union Tech Z4 (based on the Z2 severe Service Floating Seat Technology) allows for removal and replacement of metal seats. This means easier use and maintenance and no need for a specialized seat removal tool that is typical, and costly, in these kinds of applications. The Z4’s seat design is effective, economic, and easy-to-use.

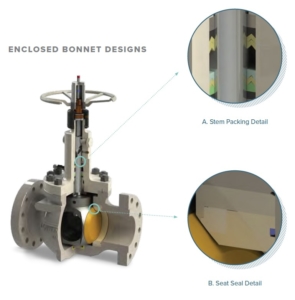

Continuing the topic of reduced maintenance efforts and better performance, we have to mention the following functional design features of the Union Tech Z4:

- Preventative design of the trunnion & bushing. Non-linear design and near-seal tolerances means this particle migration into the trunnion pocket are mitigated.

- Position indicator O-Ring prevents water from entering the bonnet.

- Bonnet nut socket head cap screws extend the durability in harsh process and climate environments.

- Twin stem guide pins enhance the stability of mechanical operation.

- Hardened stem channels with closed radius prevents over-travel.

Wrapping It Up

It’s clear to see why we at Pioneer believe in this product. The benefits of this finely designed and manufactured product make it an easy choice for our lineup of offerings. If you want to learn more about what Union Tech has to offer, check out their page here.

For more updates on our product line, featured products, industry topic exploration, company updates and more, follow our blog and opt in by submitting your email!

Get More Information on the Union Tech Z4

To learn more about the Union Tech Z4 or want to put in an order, contact us today!

Copyright Independent Balkan News Agency, 2021

https://www.pioneerindustrial.com/wp-content/uploads/2021/11/Biogas-Plant.jpeg

1048

2000

Karrie Williams

https://www.pioneerindustrial.com/wp-content/uploads/2020/12/Pioneer-Logo-Color-min.png

Karrie Williams2021-11-17 21:25:392021-11-17 21:25:44Waste Burner Systems

Copyright Independent Balkan News Agency, 2021

https://www.pioneerindustrial.com/wp-content/uploads/2021/11/Biogas-Plant.jpeg

1048

2000

Karrie Williams

https://www.pioneerindustrial.com/wp-content/uploads/2020/12/Pioneer-Logo-Color-min.png

Karrie Williams2021-11-17 21:25:392021-11-17 21:25:44Waste Burner Systems

Harnessing Natural Fluid Flows – An Exploration of Alternative Energy Sources Industries

Environmental Safety, Renewable Energy

Copyright Independent Balkan News Agency, 2021

Copyright Independent Balkan News Agency, 2021