Copyright Independent Balkan News Agency, 2021

https://www.pioneerindustrial.com/wp-content/uploads/2021/11/Biogas-Plant.jpeg

1048

2000

Karrie Williams

https://www.pioneerindustrial.com/wp-content/uploads/2020/12/Pioneer-Logo-Color-min.png

Karrie Williams2021-11-17 21:25:392021-11-17 21:25:44Waste Burner Systems

Copyright Independent Balkan News Agency, 2021

https://www.pioneerindustrial.com/wp-content/uploads/2021/11/Biogas-Plant.jpeg

1048

2000

Karrie Williams

https://www.pioneerindustrial.com/wp-content/uploads/2020/12/Pioneer-Logo-Color-min.png

Karrie Williams2021-11-17 21:25:392021-11-17 21:25:44Waste Burner SystemsBiogas is produced by the natural degradation of organic materials. This gas can be used in burners to produce energy, or it can be saved for sale or use elsewhere as a natural gas product. Sometimes there isn’t enough quantity for the gas to be saved or used economically. So, if there is an excess of biogas being produced it is oftentimes the best solution to burn off the waste gas to atmosphere.

What is Flaring?

For those unfamiliar with the process of flaring, the thought of adding to CO2 emissions for no gain may seem like a bad idea. However, it’s much better than the alternative. If excess process gas is not flared, then you are releasing much more harmful chemicals to the atmosphere and surrounding environment. These chemicals are known as volatile organic compounds (VOCs). They pose a much larger threat to the environment than the compounds released when the VOCs are burned off. This is why we see flares at many industrial facilities. It’s much safer and more environmentally friendly.

Some processes may malfunction and cause excess gas as well. Excess gas can be piped off to a flare for safe handling, rather than the pressure being passed downline and creating potentially dangerous scenarios. This gives better environmental results and is critical for ensuring the integrity of the downstream process. And, most importantly, it helps ensure operator safety.

How Are VOCs Safely Dealt With?

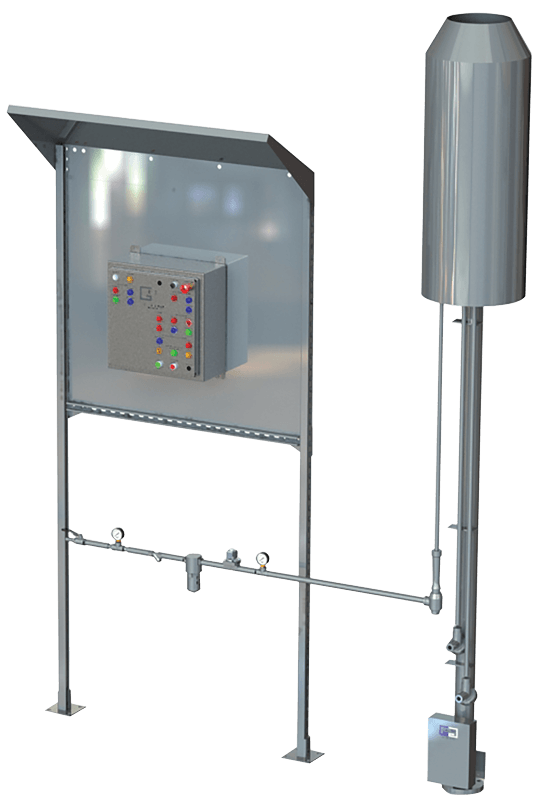

It’s an inevitable by-product of many industrial processes that VOCs are made. If they can’t be recycled, put to use within their process, or sold then we need a safe and effective way of dealing with them. This is where products like a Groth Waste Gas Burner are required. Specifically designed for biogas applications, this waste gas burner offers technology that improves efficiency, safety, and reliability in your waste gas burning operations. This Groth device offers burning capability of low BTU gas sources as well. This means that lower energy content waste gases won’t pass through unburned.

The Model 8392B Gas Burner from Groth also boasts a stoichiometric pilot flame operation resulting in a proper flame temperature for ideal burning. This means the system is able to regulate the fuel to oxygen ratio for the most efficient burning possible. This maximizes the VOCs eliminated and gives the cleanest burn possible.

In Conclusion

Now we know the purpose flares serve in an industrial environment, biogas or otherwise, and the importance they have on safety. We chose the example of the Groth Waste Gas Burner designed for biogas applications to show how well designed some of these flare systems can be. A lot of great engineering goes into ensuring a good flare product. We, of course, distribute Groth products because we can personally guarantee their performance and reliability. Feel free to contact our product experts at Pioneer Industrial if you are in need of any process control technology or have any questions concerning it.

Get More Information on Groth products or biogas processes!

To learn more about Groth products or biogas processes, contact us today!

Copyright Independent Balkan News Agency, 2021

https://www.pioneerindustrial.com/wp-content/uploads/2021/11/Biogas-Plant.jpeg

1048

2000

Karrie Williams

https://www.pioneerindustrial.com/wp-content/uploads/2020/12/Pioneer-Logo-Color-min.png

Karrie Williams2021-11-17 21:25:392021-11-17 21:25:44Waste Burner Systems

Copyright Independent Balkan News Agency, 2021

https://www.pioneerindustrial.com/wp-content/uploads/2021/11/Biogas-Plant.jpeg

1048

2000

Karrie Williams

https://www.pioneerindustrial.com/wp-content/uploads/2020/12/Pioneer-Logo-Color-min.png

Karrie Williams2021-11-17 21:25:392021-11-17 21:25:44Waste Burner Systems

Harnessing Natural Fluid Flows – An Exploration of Alternative Energy Sources Industries

Environmental Safety, Renewable Energy